Rhodium Plating White Gold Jewellery

As we are a workshop, we offer to undertake all services for your jewellery. Be it a clean, a polish or the removal of major/minor dents and scratches, it is all done in house.

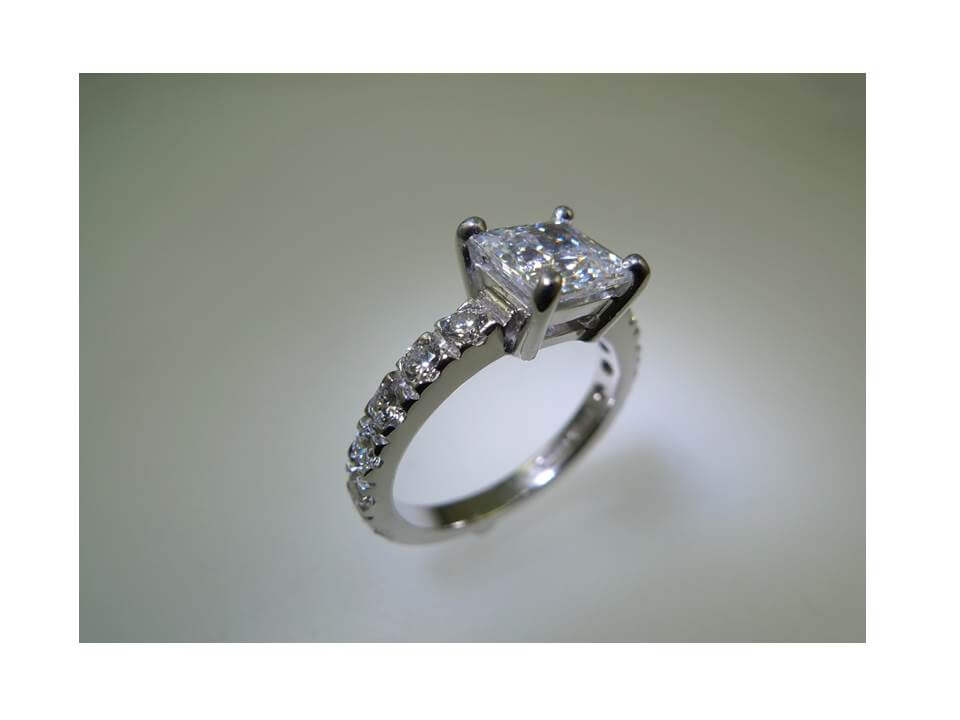

We get a lot of enquiries from owners of WHITE GOLD jewellery who believe that their jewellery has tarnished, discoloured, yellowed or faded.

The truth here is it has not. White gold, like all golds, is an alloy. In the form of 18 carat, white gold contains 75% of fine gold (an orange colour metal) – the same amount as in yellow gold. The difference between the alloys being that the yellow gold is alloyed with yellow metals and the white gold with white metals. With 75% gold and 25% white metal, it is easy to realise how white gold’s natural colour is actually an ‘off white’ metal with a yellow tinge.

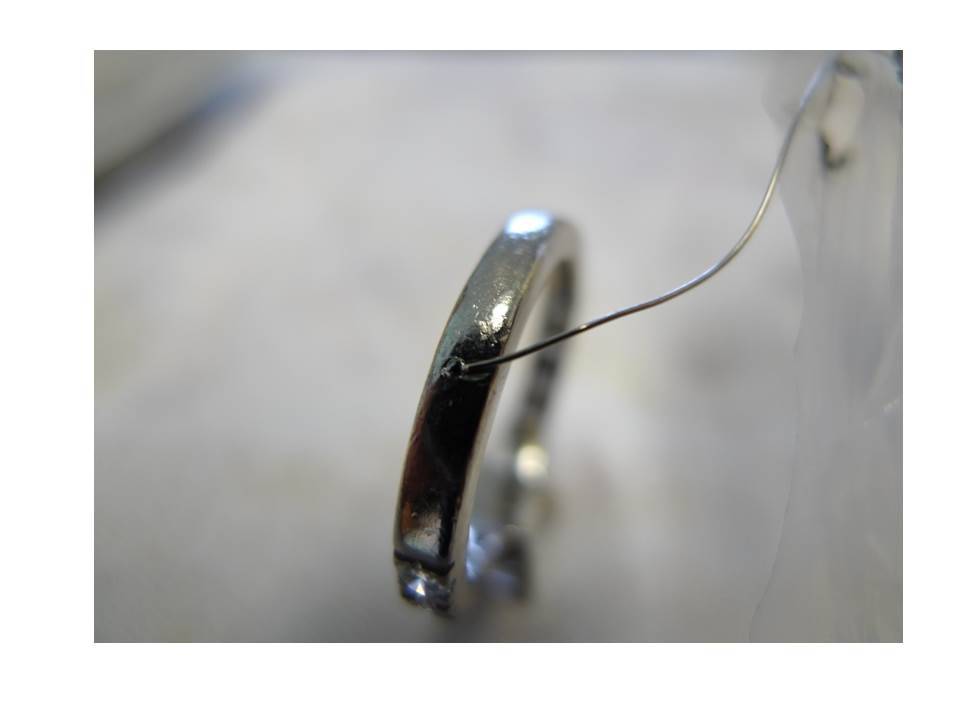

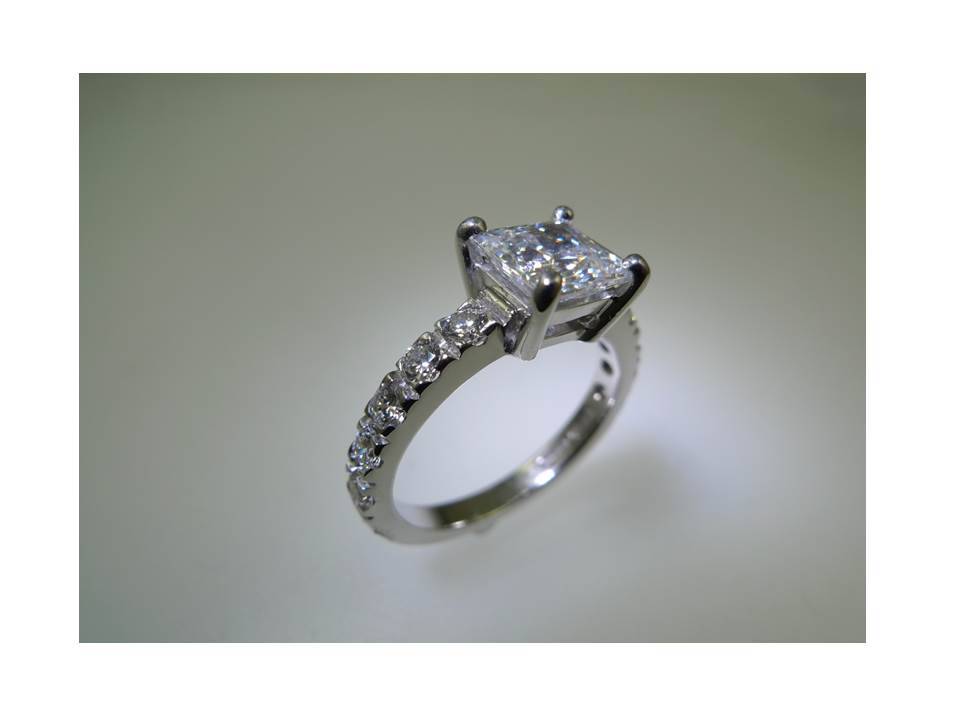

When White Gold jewellery is made, it is RHODIUM plated as a final finish. Like all plating, this is a very fine layer and despite rhodium being very hard, it will wear off over time. Depending on how ‘hands on’ the wearer is, this can be as quick as a few weeks. Usually, it is most visible at the back of a ring, as this is the part that most regularly comes into contact with other objects to cause the wear.

People ask if we ‘Dip’ jewellery. This is a misleading term. We believe people are likening this to ‘silver dip’ whereby tarnished silver is put in sulphur smelling liquid to remove the tarnish. As said before, this is not a tarnish. So the jewellery has to be properly prepared before a new plating layer is applied. If we were simply to re-plate a ring without proper surface preparation, the finish would be extremely poor.

So, here’s what happens:

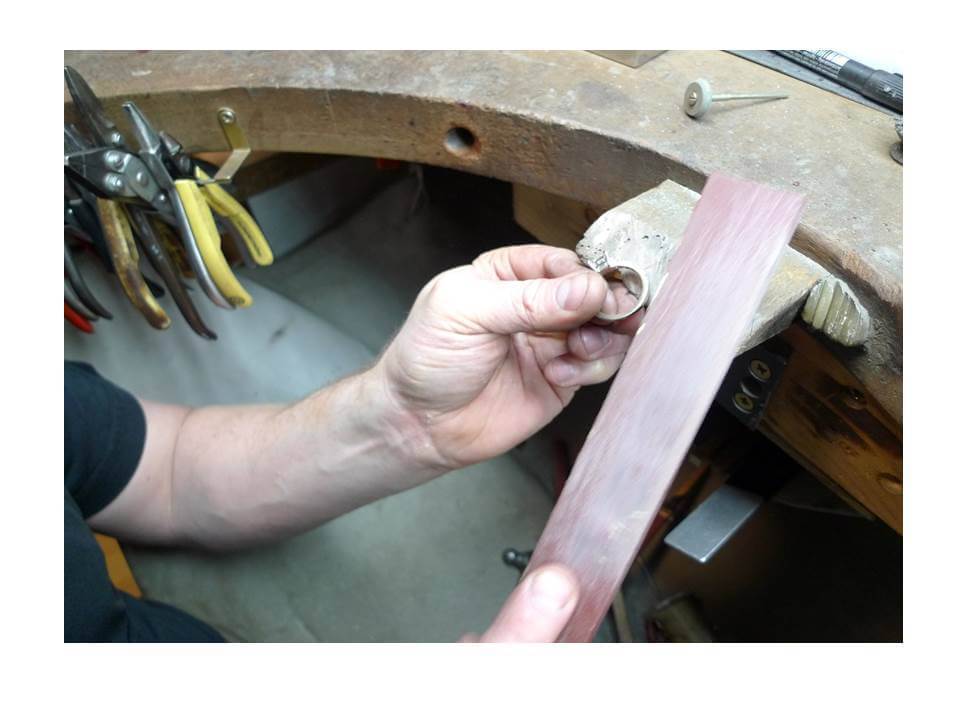

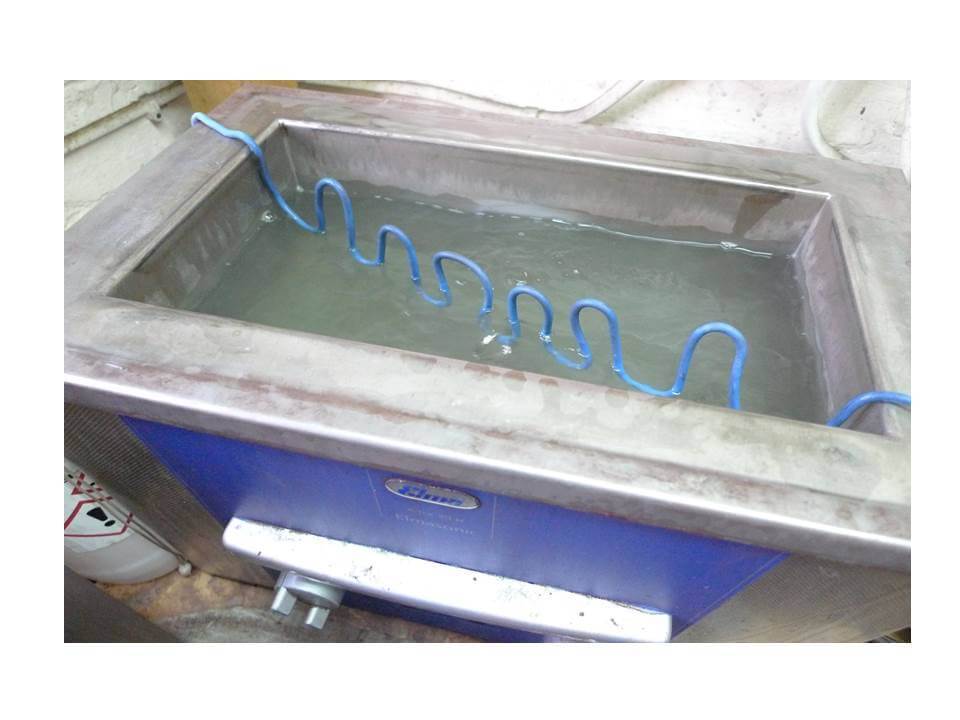

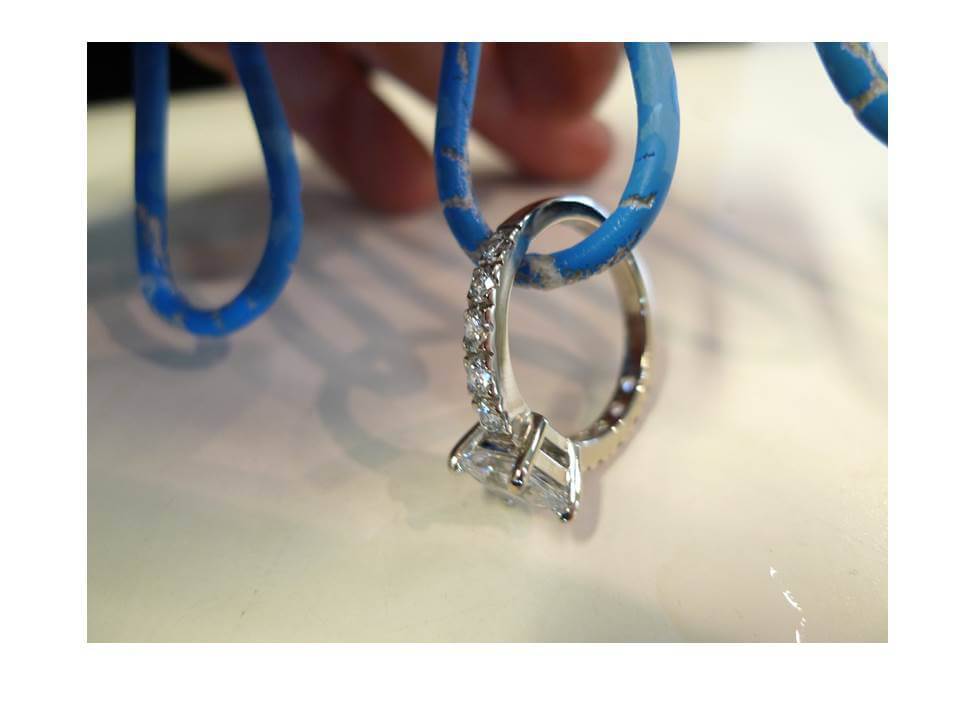

Firstly, we clean the item to remove any dirt. It’s then carefully examined to check for damage to stones, loose stones or damage to claws. Then any major dents are filled by laser weld. After this, the item is rubbed down with abrasive paper. This removes any minor scratches and also any old rhodium plate. Its then polished with an abrasive grease. Then cleaned again. Then polished with a finer lustre polish. Then it’s cleaned again. Finally the electroplating process. The item is cleaned with electrolytic acid cleaner. After a rinse with de-ionised water, its plated with very high quality rhodium.

This entire process takes around 30 minutes. For this reason, we are very happy to carry out while you wait rhodium plating and most certainly same day rhodium plating. We even welcome you to watch. Your piece of jewellery will look brand new again. Some clients even comment it looks better than when it was new, something we love to hear!

Call us on 01444 471380 or contact us via our contact form for more information – you will be glad you did.